The fusion of mechanical, electrical and software engineering.

Products

HNC

CNC MACHINE TOOL

CNC APPLICATION SOFTWARE

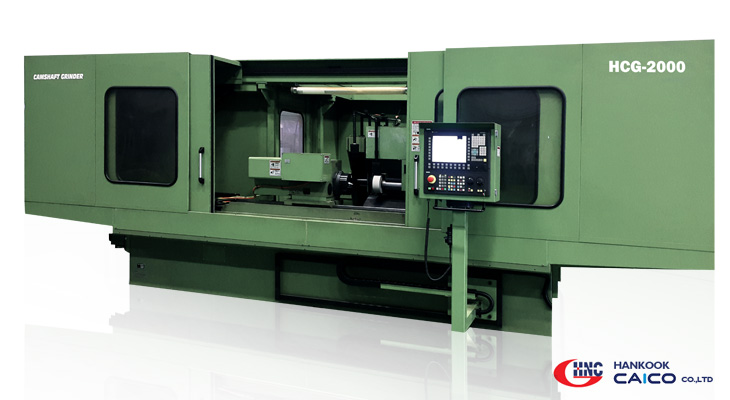

CNC CAM GRINDING MACHINE

HCG-2000

| ITEM | UNIT | HCG-2000 |

|---|---|---|

| Max. working diameter | mm | Ø360 |

| Distance between center | mm | 2,050 |

| Center spec. | MT | MT 5 |

| Max. wheel diameter (Out x Thick x Inner) |

mm | Ø510X100XØ228.6 |

| Max. wheel speed | rpm | 1,200 |

| Max. Sub. Wheel diameter (Out x Thick x Inner) |

mm | Ø200x100xØ32 |

| Max. Sub wheel speed | rpm | 4,000 |

| Workbed rapid feedrate | mm/min | 6,000 |

| Wheelhead rapid feedrate | mm/min | 5,000 |

| Machine dimension | mm | 7,125x2,950x2,275 |

| Machine weight | Ton | 12 |

| CNC controller | SIEMENS 840D sl |

- Machine structure : X-axis(Wheel feed), Z-axis(Work feed), C-axis(Work rotation), SP(Wheel spindle)

- C-axis adopts servo motor + Heidenhain high accuracy rotary encoder.

- X-axis adopts servo motor + ball screw + Heidenhain Linear scale.

- Dual wheel spindle system (out diameter Ø400 or Ø200 wheel spindle can be used alternatively)

- Water cooling wheel spindle motor is adopted for preventing heat deformation and maintenance free.

- Dittel AE monitoring system is equipped to monitor actual grinding and wheel dressing.

- Not only ship engine Cam but also automobile Cam-shaft can be ground.

- Magnet separator and Paper filter system are installed in coolant system.

- Special CAM grinding software package is installed Go CAM grinding software package