The fusion of mechanical, electrical and software engineering.

Products

HNC

CNC MACHINE TOOL

CNC APPLICATION SOFTWARE

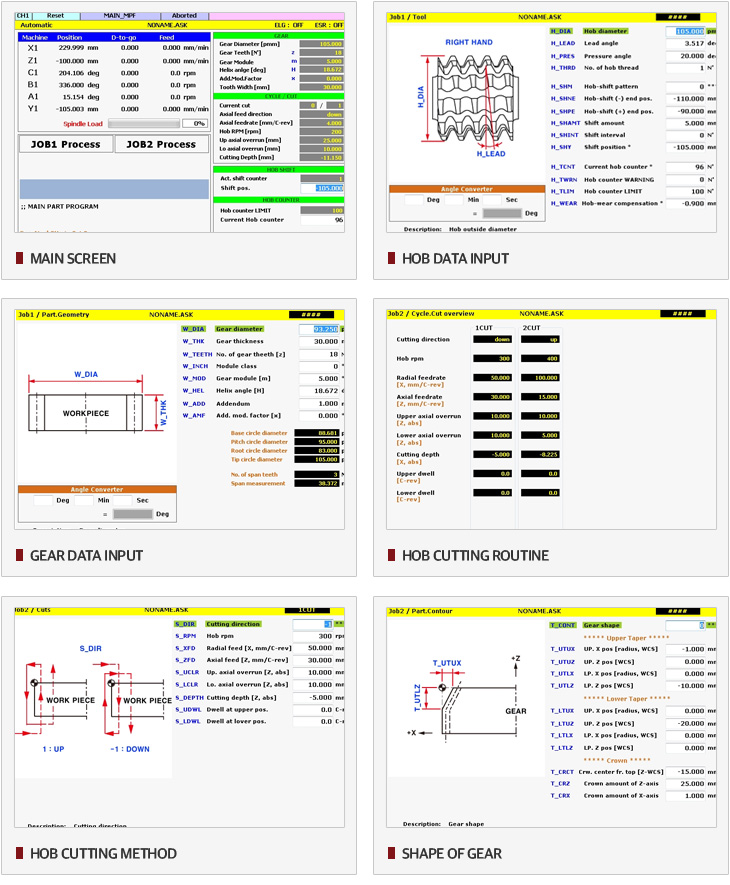

Gear Hobbing Software

This software assist CNC gear hobbing machine which generate gear with rotating tool-gear hob. We have to change the gear combination every time according to the gear specification - number of teeth and helical angle- in manual machine.

The spindle motor supplies every power to rotating hob tool, cutting feed axis and work table. Nowadays, the modernized CNC controller provides special synchronization function called "Electrical gear". The high qualiity gears are manufactured easily with the assistance this function. But it is not easy task for machine operator to edit CNC machining program for every different gear.

This software package offers interactive programming for gear cutting, what you have to do is that gear and hob data input, workpiece setup and push cycle start. HMI for interactive programming, CNC grinding cycle program, and PLC program are integrated in this program package together.

Function description

- Gear data input : gear module, number of teeth, helical angle, modulation factor, gear width etc.

- Hob data input : gear module, number of thread, lead angle, hob width, hob diameter etc.

- Shape of gear : gear shape selection - straight, taper, crowning

- Hobbing routine : define the stroke - spindle speed, cutting direction, cutting feedrate etc.

- You can define the method of hob shift, shifting amount, and hob shift interval count.

- You can cut 2 gears in one workpiece by installing 2 hobs in spindle arbor.

- Menu screen for worm gear cutting (Tangential cutting is possible.)

- Emergency retraction function in case of serious machine alarm or power failure (Capacitor module and battery module equipped)