The fusion of mechanical, electrical and software engineering.

Products

HNC

CNC MACHINE TOOL

CNC APPLICATION SOFTWARE

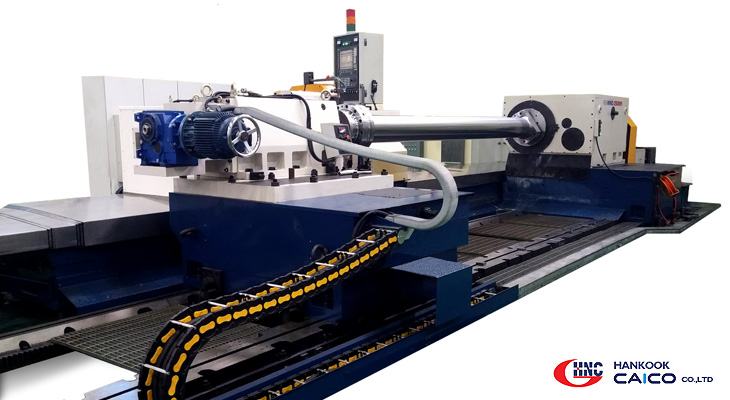

CNC ROLL GRINDING MACHINE

HNC-250M1

| ITEM | UNIT | HNC-250M1 |

|---|---|---|

| Max. working diameter | mm | 2,000 |

| Min. working diameter | mm | 160 |

| Max. work weight | Ton | 15 |

| Distance between center | mm | 5,000 |

| Max. wheel diameter (Out x Thick x Inner) |

mm | Ø900X120XØ254 |

| Max. wheel speed | rpm | 200-600 |

| Max. work speed | rpm | 5-30 |

| Carriage max. feedrate | mm/min | 0-5,000 |

| Machine dimension | mm | 1,5000X5,200 |

| Machine weight | Ton | 25 | CNC controller | SIEMENS 840D sl |

- Machine structure : X-axis(Wheel feed), Z-axis(Carriage feed), U-axis(Crowning), C-axis(Work rotation), SP(Wheel spindle)

- Universal machine structure grinding steel roll, paper roll and industrial roll etc alternatively.

- Moveable headstock and tailstock in radial direction to workpiece (Grinding diameter 160~2,000mm)

- Modular center system in headstock and tailstock, dead or live center can be installed alternatively.

- Clamping chuck can be installed on the headstock plate for paper roll grinding.

- 2 stage gear box and belt driven reducer are adopted in work spindle to reduce the noise and vibration.

- Semi-Hydrostatic system for carriage feeding lubrication.

- CNC controlled Tilting axis(U-axis) for the shape grinding of roll.

- Hydrodynamic wheel spindle for reducing the vibration and heat generation.

- Special Roll Grinding software package is installed. Go Roll grinding sofware package