The fusion of mechanical, electrical and software engineering.

Products

HNC

CNC MACHINE TOOL

CNC APPLICATION SOFTWARE

Camshaft Grinding Software

In cam grinding process, the contact line of grinding wheel and cam is not on the line which connect between center of grinding wheel and the center of cam. The contact line is changed from the previous contact line, if wheel spindle become smaller by wheel dressing. We need difficult algorithm to calculate the contact line based on the shaped of cam and current wheel diameter.

Our Camshaft Grinding Software Package support the cam grinding for automobile and ship engines. This program package can be installed in PC for HMI(PCU) of Siemens 840D CNC controller. HMI for interactive programming, CNC grinding cycle program, and PLC program are integrated in this program package together.

The sub menus are cam data input menu, machining routines, grinding simulation, management of cam types etc. Automatic cam grinding process is started just only by pushing cycle start switch after cam data input and machine setup. This program package can be used in cam milling machine and noncircular grinding machines too.

Function description

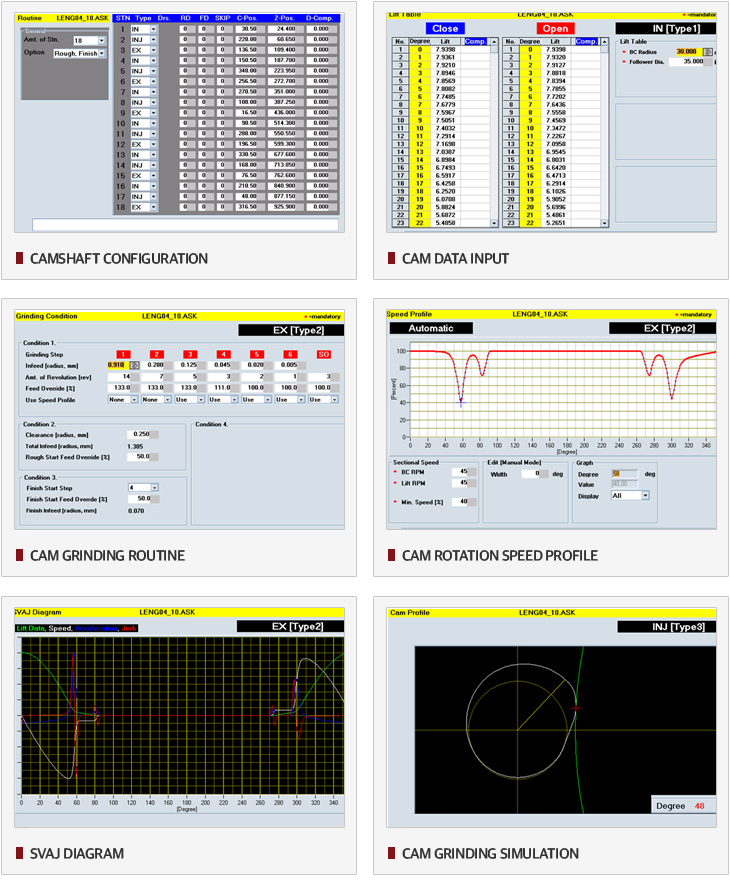

- Camshaft configuration : you can configure the arrays of cam in camshaft - inlet, outlet or injection cam etc.

- Cam data input : you can input tappet lift value according to cam rotation angle of the each cam.

- Cam grinding routine : you can define the grinding process - coarse, fine and sparkout grinding.

- Cam rotation speed profile : the peripheral speed of C-axis(Workpiece rotation) must be constant to maintain the identical roughness of ground surface. You can also modify the speed profile manually with the automatically calculated speed profile.

- SVAJ diagram : We display the graph representing tappet lift(S), velocity(V), acceleration(A), and jerk(J) according to cam rotation angle.

- Grinding simulation : you can simulate the cam grinding based on the selected cam lift data and the actual sized grinding wheel. You can alter the cam speed profile after simulating the cam grinding by rotating cam in every 1degree. The contact point of cam between wheel is displayed as red crosshair.